Replacing the oil pump with the engine in the car is one of the most demanding jobs on a 3000gt/stealth and is not for a beginner.

If possible it should be

replaced during a timing belt/water pump service because it requires belt removal. The main reason to change the pump is when

low oil pressure gauge is read on aftermarket gauges; the stock gauge is not accurate enough to gauge. If low pressure is suspected

there are many things that can cause this, old high mileage between changes, oil filter (I've found stock mitsu to be the best),

rod/main bearing clearances, dented oil pan restricting flow, or bad oil pump. Be sure to follow your service manual for detailed

assembly/disassembly as I am not

responsible for damages due to improper assembly. This is not meant as

a guide to replacing/properly tensioning the timing belt. You should

have expierience doing that or at least the ability to follow the

manual

Tools needed: various sized sockets from 10mm to 22mm, crescent wrench, timing belt tensioner tool, torque wrench, auto tensioner pin (1.4mm

in diameter), oil pan gasket (I used permatex ultra grey),

Parts needed: Of course you will need a new oil pump and various seals and gaskets. These are assuming a 1992 RT/TT however you should double

check with your parts dealer for your vehicle.

MD189779 GASKET,OIL FILTER BRACKET

MD189778 GASKET,OIL PUMP

MD175583 OIL PUMP

MD183239 GASKET,OIL STRAINER

MB033054 GASKET, OIL COOLER LINES (quantity 4)

MF660063 GASKET, TURBO FEED LINE CRUSH WASHER (quantity 2)

MR258477 GASKET, TURBO RETURN LINE (quantity 2)

Pre-removal: Downpipe, transfer case, starter, oil pan, alternator, left frame member, and accessory/ps belt.

Tip: Don't bother struggling with the oil filter if it's stuck, it will be easier to get at later.

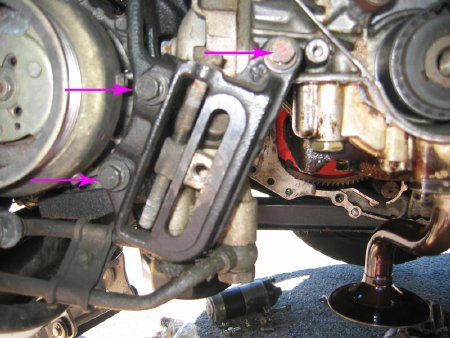

Unbolt the alternator tensioner bracket.

There are three long bolts holding the compressor on the bracket. One on the top and two on the bottom. The bottom two are easier to wrench from underneath the car.

Now we can start unbolting the bracket, there are 6 bolts total. Red arrows show Ac Compressor bolt locations. Take care to remember or write down the bolt locations as they are different sizes.

Last two.

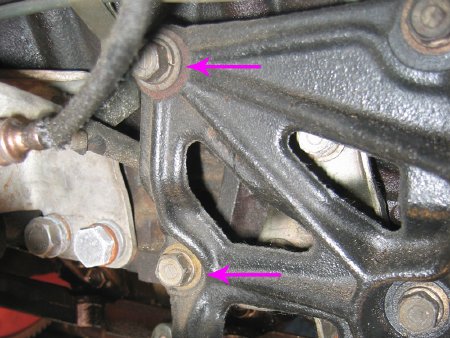

Here we can see the bracket removed.

Now we can remove the timing belt tensioner pulley. Before starting line up the marks on the crank sprocket and cam gears. Also put binder clips on the cam gears to be sure they stay in their position. To save yourself some time at the vise, place the pin in the auto tensioner before unbolting the pulley, if it won't go in try putting some pressure on the pulley bolt, this will allow the tensioner rod to move in or out a bit to facilitate pin installation.

Next, remove the auto-tensioner.

The only thing left is the bracket the tensioner pulley swings on.

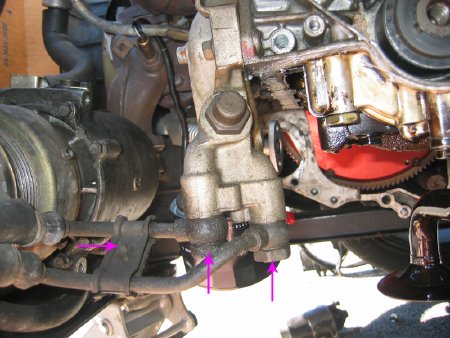

Remove the oil cooler line connections and bracket holding the hardlines together. Be careful as the compressor has a tendency to rest on the lines so I supported it with some wire. I didn't have a big enough socket so I used a crescent wrench without any problems. Be sure to keep an oil pan handy as these will leak oil. At this point you will have more access to get a stuck filter unscrewed.

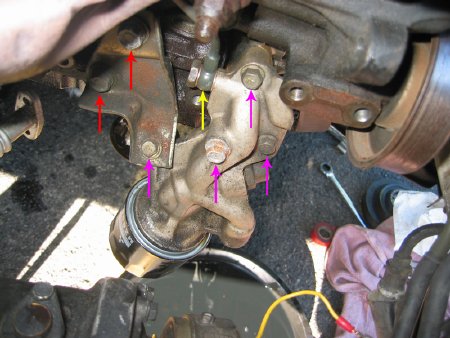

Now it's the filter assembly. First start off by loosening the turbo feed banjo bolt(yellow). If you can't remove the bolt try removing the filter bracket (red). Now you can unbolt the 3 bolts which bolt the housing to the side of the pump. Be sure to keep track of the bolts as they are different sizes.

Housing removed.

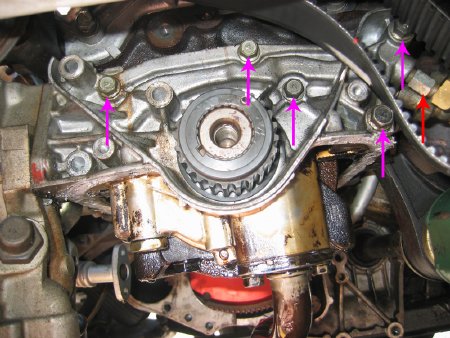

Before unbolting the oil pump remove the pressure sender aftermarket or stock(red). There will be 5 bolts holding the oil pump in place. After that the pump should come off. The bolts are different sizes so take care to remember or write down locations.

Pump Bolts.

Pump Gone.

New and old pump.

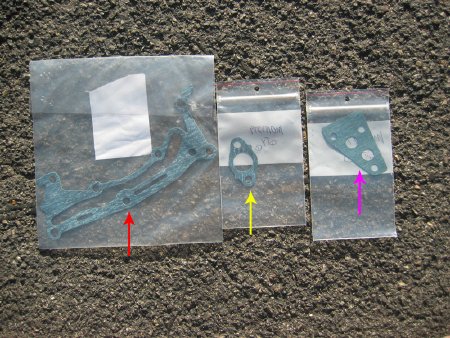

Oil Pump(red), strainer(yellow), and filter housing(purple) gaskets.

Be sure to clean off all old gasket material, you do not want this to leak. Ensure proper gasket alignment so the channels are not blocked. The use of gasket adhesive may make installation easier.